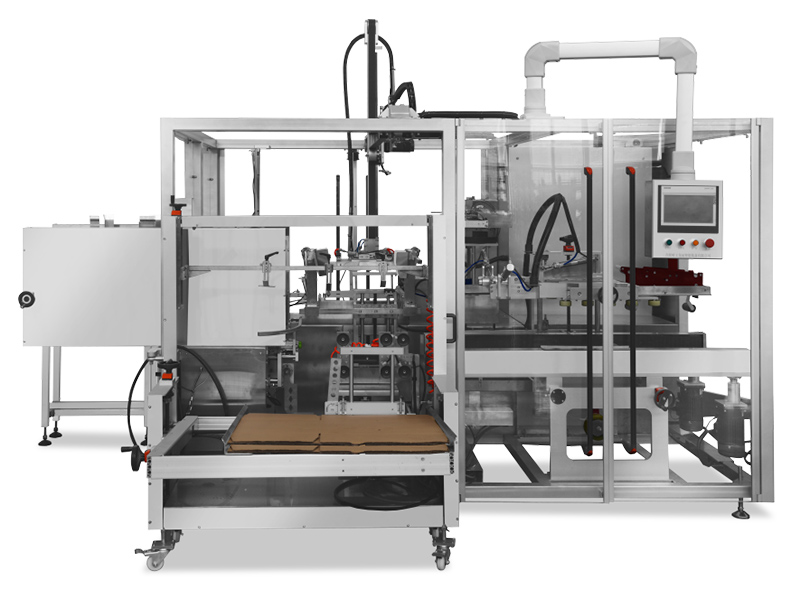

MODALIDAD: Máquina de envasado Seelong-carton Slcp-550a

VENTAJAS 1 : Nueva integración mecánica y eléctrica de equipos de embalaje automáticos que combinados con tecnología avanzada en el país y en el extranjero;

VENTAJAS 2: Sistema de paletización automática, sistema de desempaque, sistema de envasado y sistema de sellado, colocación automática de cuerpo de placa superior e inferior y colocación automática de los organismos de certificación;

VENTAJAS 3: Adopta el sistema de control de PLC y el sistema operativo de la interfaz de máquinas de máquinas de 14 pulgadas;

APLICACIÓN: Puede usar solitario o uso con equipo frontal para completar las maquinarias de finalización de la línea

Artículo No:

KZF-550AOrden (MOQ):

1 PCPago:

T/T; L/C; WESTERN UNIONOrigen del producto:

CHINAColor:

WHITE+SILVERPuerto de embarque:

SHANGHAI; SHENZHEN; NINGBO; QINGDAO; GUANGZHOUTiempo de espera:

15-30DAYSPeso:

1300KGMáquina de envasado SEELONG-CARTON SLCP-550A

Descripción del producto:

SLCP-550A Seelong- Carton La máquina de embalaje de nuestra empresa es el desarrollo de una nueva integración mecánica y eléctrica de equipos de embalaje automáticos que se combinan con tecnología avanzada en el país y en el extranjero. La máquina integra el sistema de paletización automática, el sistema de desempaque, el sistema de embalaje y el sistema de sellado, la colocación automática del cuerpo de la placa superior e inferior y la colocación automática de los organismos de certificación. Adopta el sistema de control de PLC y el sistema operativo de la interfaz de la máquina de máquinas de 14 pulgadas. La apertura y la acción de embalaje se terminan mediante el mecanismo de servo. Esta máquina es adecuada para una variedad de productos de especificación que empaquetan automáticamente. Puede usar solitario o uso con equipo frontal para completar maquinarias de final de línea.

Característica:

1. Sistema de control de PLC, sistema operativo de interfaz de máquina de man-máquina. Tiene funciones de contar, paletizar, desempacar, embalar y sellar automáticamente, etc.

2. El sistema de paletización automática es ajustable según el tamaño de la caja de cartón y las formas de paletización.

3. Velocidad de embalaje: Rápido, alcanzando 10 veces al menos.

4. El mecanismo de apertura y embalaje adopta servo drive y estable.

5. La máquina tiene una fuerte compatibilidad, lo que significa que todas las piezas de ajuste están equipadas con la tabla de la rueda de ajuste y la tabla de escala.

6. Con alarma de falla, falta de alarma de material, sin alarma de caja, alarma de la máquina de tarjetas y otras funciones.

Parámetros técnicos principales:

Aplicación de cartón | Max: L550 * W350 * H350mm MIN: L300 * W180 * H150MM |

Velocidad de embalaje | De acuerdo con el número de capas de embalaje, la velocidad del manipulador alcanza 10 veces / min al menos. |

Suministro eléctrico y poder | 220V / 50Hz, 5.5kw |

Presión del aire | 0.6MPA |

Peso | 1300kg |

Dimensiones externas | L4000 * W2900 * H1850MM |

PD: Los datos anteriores son los parámetros estándar. OEM está disponible | |